In today’s extremely competitive marketplace, design thinking is no longer enough to give brands the market edge. Current product success rates are in the range of fifty percent at best. And success rates for new businesses linger around twenty-five percent. To Launch a successful product you must parallel look in to and seamlessly integrate the emerging ‘Market opportunities’ with emerging ‘Technology opportunities’. We at Teams partner with you in converting your requirement to a design idea and enable you to move faster in to market

On manufacturing and realizing the Design in to a physical product aspect, business must navigate greater complexity than ever before due to quickly changing market needs. To thrive in the dynamic market, manufacturing companies not only have to embrace new technology, but also stay focused on the foundational elements and principles of manufacturing performance which is the building block of any company.

We have developed our capabilities to help you prepare for new reality and evolve the necessary resiliency in dynamic market. Using these capabilities we enable you to establish / re-align systems and procedures, blend human and technological capabilities to achieve superior outcomes.

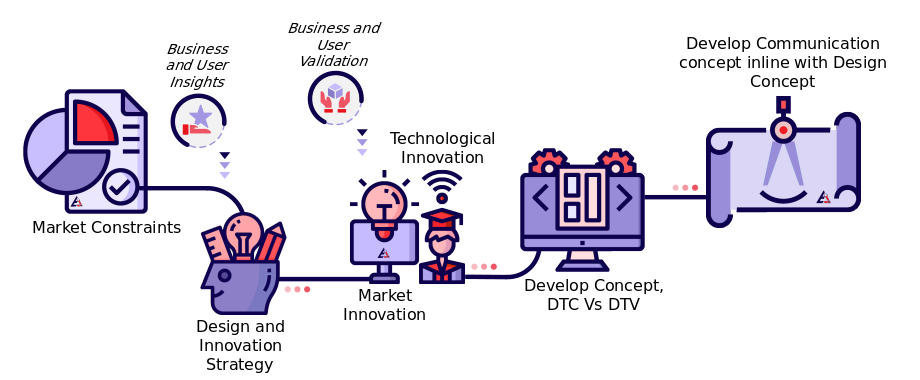

New Product Development

Product design cost accounts for only about 5% of a product’s total cost, however, it dictates about 70% of the product's total accounted manufacturing cost. we integrate value engineering strategies across your entire value chain, optimizing the product design, from functionality to cost and improving the value for development, production and supply chains.

Our team works on adding the highest possible value into your product, in terms of function, ergonomics, aesthetics and durability, Manufacturing, Labor, Logistics and Serviceability

We take utmost care in designing the product, by understanding your exact needs. We evaluate the Design to Value (DTV) Vs Design to Cost (DTC) principles and bring in the features suiting your target audience and product’s positioning

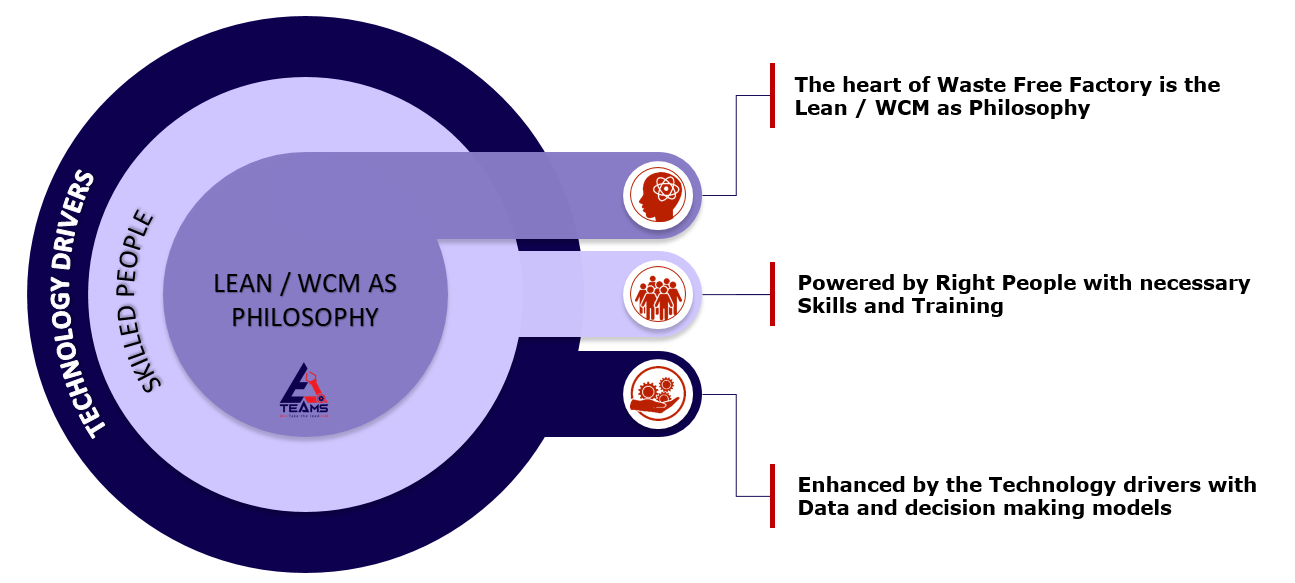

Hybrid Factory

With so much technological advancements, how do companies decide on the best automation strategy? We should not get carried away with automation for its own sake, as it will result in almost always projects that cost too much, take too long to implement, and fail to deliver against their business objectives.

A successful automation strategy requires right decisions on multiple levels. Companies must choose which activities to automate, what level of automation to use (from simple programmable-logic controllers to highly sophisticated robots guided by sensors and smart adaptive algorithms), and which technologies to adopt.

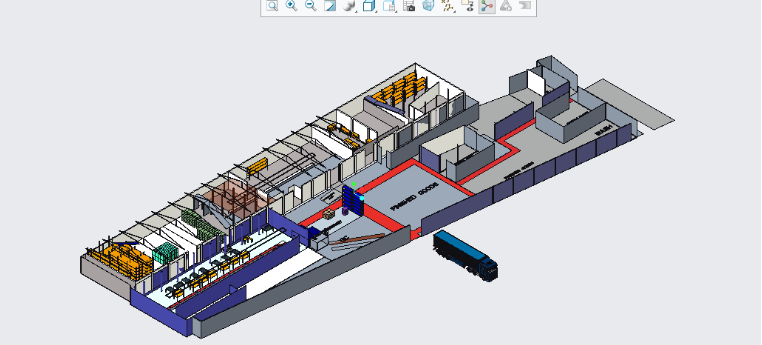

We work with you in deciding the right level of automation aligning to your current status and future plans and help you set up a “Hybrid Factory” which has right mix of Automation and conservative processes.

Hybrid Factory Framework

Big Data Analytics

For decades, many of the world’s best companies have used their production systems as a source of sustainable competitive advantage. Success depended on ability to improve continually at a pace the competitors struggle to match.

Today, even the best of the companies can boost their performance one step further using huge volumes of data on processes and performance generated by new generations of network-connected devices (IoT) inside the factory. To use the opportunity, companies must revisit and recheck many of the processes and principles that have been so successful for them in the past.