- Home

- Services

Intelligent Engineering, Precise Results

We deliver lifecycle-aligned solutions across engineering, smart factory systems, and digital transformation. From PLM-enabled NPD to intelligent manufacturing and scalable digital platforms — our services are engineered for precision, speed, and sustainability.

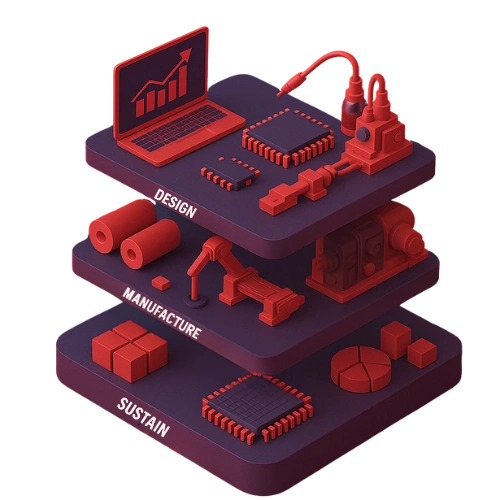

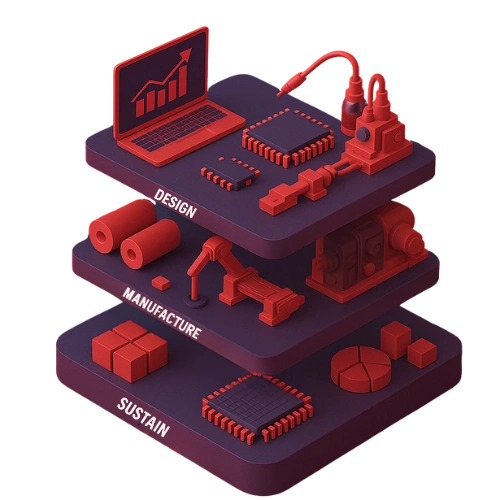

Product Engineering

Transform concepts into market-ready innovations with AI-enhanced design, optimized PLM solutions, and strategic engineering consulting.

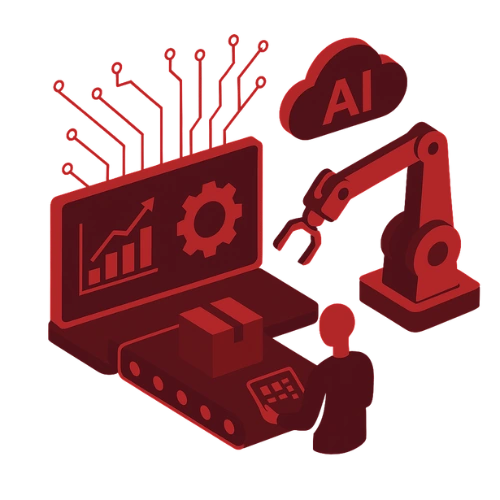

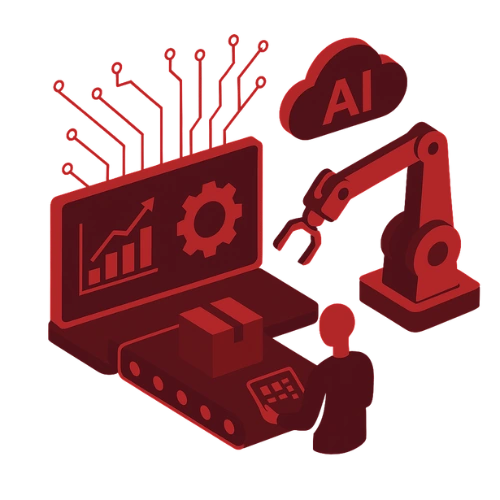

Smart Manufacturing

Boost operational excellence by integrating cutting-edge automation, real-time analytics, and predictive maintenance for production lines.

Digital Solutions & Consulting

Drive digital transformation through advanced IoT frameworks, AI-driven platforms, and insights that shape the factory of the future.

- Industries

- Events

- Explore TEAMS Tech

Where Engineering Meets Identity

We bring engineering to life through culture, collaboration, and curiosity. From growing future-ready talent to co-creating with global partners—TEAMS Tech is built on people who design with purpose and deliver with precision. This is where our journey, values, and vision come together.

About Us

We are a precision-driven engineering firm accelerating smart factory innovation through lifecycle-aligned solutions—from NPD to PLM and beyond.

Careers

Join a team that thrives on solving real-world challenges in manufacturing, product design, and digital transformation—where your ideas build what’s next.

Contact Us

Let’s talk engineering, strategy, or transformation. Reach out and explore how we can co-create smarter, scalable solutions for your business.

- Home

- Services

Intelligent Engineering, Precise Results

We deliver lifecycle-aligned solutions across engineering, smart factory systems, and digital transformation. From PLM-enabled NPD to intelligent manufacturing and scalable digital platforms — our services are engineered for precision, speed, and sustainability.

Product Engineering

Transform concepts into market-ready innovations with AI-enhanced design, optimized PLM solutions, and strategic engineering consulting.

Smart Manufacturing

Boost operational excellence by integrating cutting-edge automation, real-time analytics, and predictive maintenance for production lines.

Digital Solutions & Consulting

Drive digital transformation through advanced IoT frameworks, AI-driven platforms, and insights that shape the factory of the future.

- Industries

- Events

- Explore TEAMS Tech

Where Engineering Meets Identity

We bring engineering to life through culture, collaboration, and curiosity. From growing future-ready talent to co-creating with global partners—TEAMS Tech is built on people who design with purpose and deliver with precision. This is where our journey, values, and vision come together.

About Us

We are a precision-driven engineering firm accelerating smart factory innovation through lifecycle-aligned solutions—from NPD to PLM and beyond.

Careers

Join a team that thrives on solving real-world challenges in manufacturing, product design, and digital transformation—where your ideas build what’s next.

Contact Us

Let’s talk engineering, strategy, or transformation. Reach out and explore how we can co-create smarter, scalable solutions for your business.

- Home

- Services

Intelligent Engineering, Precise Results

We deliver lifecycle-aligned solutions across engineering, smart factory systems, and digital transformation. From PLM-enabled NPD to intelligent manufacturing and scalable digital platforms — our services are engineered for precision, speed, and sustainability.

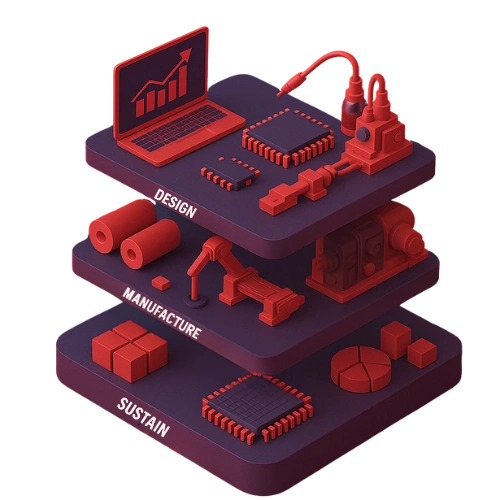

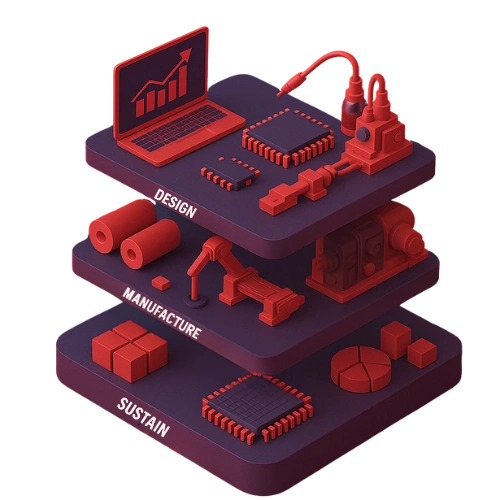

Product Engineering

Transform concepts into market-ready innovations with AI-enhanced design, optimized PLM solutions, and strategic engineering consulting.

Smart Manufacturing

Boost operational excellence by integrating cutting-edge automation, real-time analytics, and predictive maintenance for production lines.

Digital Solutions & Consulting

Drive digital transformation through advanced IoT frameworks, AI-driven platforms, and insights that shape the factory of the future.

- Industries

- Events

- Explore TEAMS Tech

Where Engineering Meets Identity

We bring engineering to life through culture, collaboration, and curiosity. From growing future-ready talent to co-creating with global partners—TEAMS Tech is built on people who design with purpose and deliver with precision. This is where our journey, values, and vision come together.

About Us

We are a precision-driven engineering firm accelerating smart factory innovation through lifecycle-aligned solutions—from NPD to PLM and beyond.

Careers

Join a team that thrives on solving real-world challenges in manufacturing, product design, and digital transformation—where your ideas build what’s next.

Contact Us

Let’s talk engineering, strategy, or transformation. Reach out and explore how we can co-create smarter, scalable solutions for your business.

- Home

- Services

Intelligent Engineering, Precise Results

We deliver lifecycle-aligned solutions across engineering, smart factory systems, and digital transformation. From PLM-enabled NPD to intelligent manufacturing and scalable digital platforms — our services are engineered for precision, speed, and sustainability.

Product Engineering

Transform concepts into market-ready innovations with AI-enhanced design, optimized PLM solutions, and strategic engineering consulting.

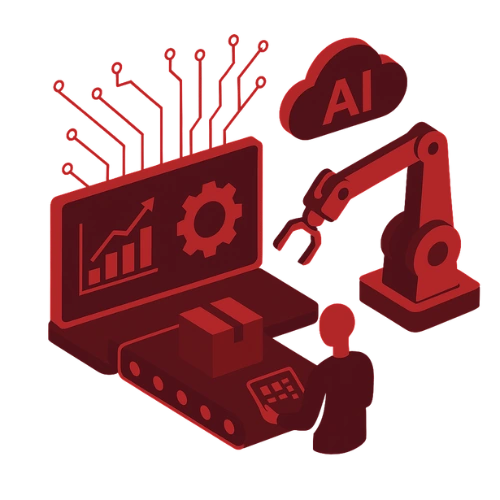

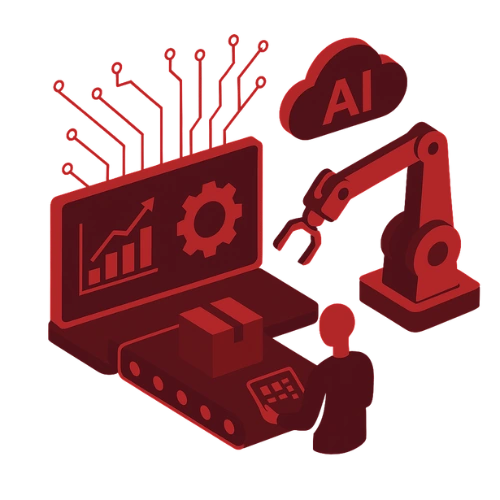

Smart Manufacturing

Boost operational excellence by integrating cutting-edge automation, real-time analytics, and predictive maintenance for production lines.

Digital Solutions & Consulting

Drive digital transformation through advanced IoT frameworks, AI-driven platforms, and insights that shape the factory of the future.

- Industries

- Events

- Explore TEAMS Tech

Where Engineering Meets Identity

We bring engineering to life through culture, collaboration, and curiosity. From growing future-ready talent to co-creating with global partners—TEAMS Tech is built on people who design with purpose and deliver with precision. This is where our journey, values, and vision come together.

About Us

We are a precision-driven engineering firm accelerating smart factory innovation through lifecycle-aligned solutions—from NPD to PLM and beyond.

Careers

Join a team that thrives on solving real-world challenges in manufacturing, product design, and digital transformation—where your ideas build what’s next.

Contact Us

Let’s talk engineering, strategy, or transformation. Reach out and explore how we can co-create smarter, scalable solutions for your business.

Mr. N Thanikasalam

Managing Director - TVESPL