What’s stopping today’s factories from becoming truly intelligent?

It’s not the lack of robots. Or dashboards. Or digital twins.

It’s the lack of clarity on where—and why—technology should be applied.

Manufacturers today face mounting pressure: volatile demand, rising product variants, and a persistent shortage of skilled labor. The instinctive response? Automate. But that often leads to automation without alignment—where digital efforts fail to deliver real impact.

At TEAMS Tech, we’ve seen this story play out repeatedly. Factories look futuristic on the surface, but struggle to scale, stay flexible, or deliver ROI. That’s when we asked a deeper question:

“What if the answer isn’t more automation, but the right mix of it?”

That question led to our Hybrid Factory Framework—a design approach that combines lean thinking, selective automation, and adaptive digital systems into a resilient, performance-driven model.

Why Manufacturers Get Automation Wrong

Let’s start with a paradox: 70% of industrial transformation efforts fall short of ROI expectations, yet the race to automate continues. But automation can’t fix a broken process—it often amplifies inefficiencies rather than eliminating them.

In one engagement, a client sought to automate a bottleneck. But the real issue was flow imbalance from upstream processes. We redesigned the layout, embedded real-time visibility, and automated only one critical step.

The result?

- 28% reduction in downtime

- 15% drop in energy use

- 100% target achievement for three consecutive months

It wasn’t technology alone—it was clarity and alignment that delivered results.

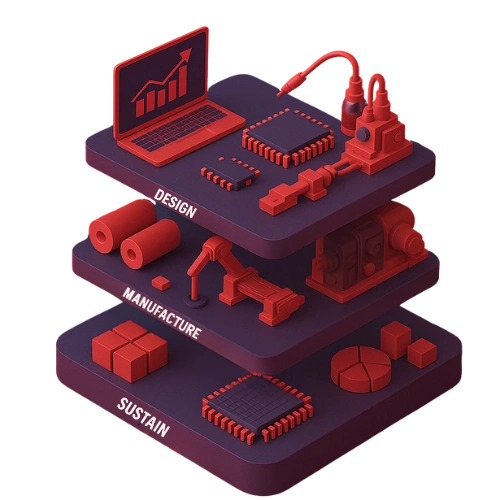

So, What Is a Hybrid Factory?

A Hybrid Factory isn’t a compromise between manual and automated. It’s a system designed with purpose.

It’s where:

- Lean principles streamline waste before digitization

- Automation is applied with precision, not excess

- Data enables prediction and responsiveness

- People are empowered, not replaced

Take Siemens’ Amberg plant—widely recognized as a global benchmark. While 75% of operations are automated, humans still perform 25% of critical tasks. The result? A staggering 99.999% quality rate, with over 1 million products made monthly (Siemens).

That’s not a contradiction—it’s the Hybrid Factory in action.

Why This Approach Matters Now

Ask yourself:

- Can your current systems adapt to last-minute changes?

- Are your teams proactively solving issues—or reacting to them?

- Is your automation helping you scale—or limiting you?

As complexity and labor challenges grow, full automation isn’t always the answer. Instead, agility and balance are the new advantage.

Consider this:

- Companies blending lean and Industry 4.0 reduce conversion costs by up to 40%, versus 15% with either alone (BCG).

- Unilever’s hybrid model improved labor productivity by 5% and cut costs by 8% across 124 plants.

- In pharma, hybrid setups with AI and robotics achieved 90% defect reduction and 4x throughput.

These are not fringe wins—they’re proof that precision beats brute force.

Why We Built This at TEAMS Tech

The Hybrid Factory Framework wasn’t drawn on a whiteboard. It’s a product of real-world observation—factories where automation failed silently, and where lean + digital succeeded by design.

We developed this to help manufacturers shift from:

- Tech-led to purpose-led

- Complex to streamlined

- Automation-first to decision-first

Because transformation isn’t just about efficiency—it’s about resilience, flexibility, and human-machine synergy. And with the right structure, it doesn’t require overhauling everything at once.